Hydrocarbon resin is a crucial tackifier in various types of adhesives, particularly Hot Melt Adhesive and Pressure Sensitive Adhesives. It finds widespread use in the packaging, woodworking, bookbinding, shoe adhesives, and sanitary products industries.

Adhesives, commonly referred to as glue, are substances that facilitate the bonding of surfaces between two objects. Compared to other connection methods, adhesives offer advantages such as lightweight, uniform stress distribution, high strength, and fatigue resistance.

Based on their different performance characteristics, adhesives can be further categorized into two types: adhesives and sealants. Any material with excellent bonding properties primarily used to bond objects together is referred to as an adhesive. Materials designed primarily for their sealing properties are known as sealants.

Furthermore, adhesives can be classified based on their chemical composition and curing method into Solvent-Based Adhesives, Water-Based Adhesives, Hot Melt Adhesives, Reactive Adhesives, and more.

HB Group's hydrogenated resins have excellent thermal stability, light color, good polymer compatibility, low odor and environmental protection. So it can be widely used in sanitary products, such as baby diapers, adult diapers, female products, pet diapers and so on.

Corresponding grades and characteristics

These applications mainly use hydrogenated resins DW100, GW100, GA100, CW100 and SIS EL9209.

Hydrogenated DCPD resins: DW100 Wide applicability, low viscosity.

Hydrogenated C9 resins: GW100 GA100, High polarity, good adhesion to polar materials.

Hydrogenated C5 resins: CW100, Good tackiness effect.

SIS EL9209: Used for Hygiene products structural adhesive, high styrene content, used as Eisai structural adhesive, with low melt viscosity, cohesion strength.

HB Group's low molecular weight C5 resins can be used in Hot Melt and Solvent-Based Pressure Sensitive Tapes to improve the initial viscosity and long-term adhesion of Pressure Sensitive Tapes. These resins are compatible with styrene butadiene rubber, butyl rubber, styrene block copolymers, polybutene, low-density polyethylene and atactic polypropylene. Common types of products used are: packaging tapes, masking tapes, double-sided tapes, duct tapes, electrical tapes, beer, toilet paper labels, etc.

Corresponding grades and characteristics

Tapes: Resins BT-2104,BT-2110, C-2120, BT-1115,BT-1300, C-2145, SIS EL9101, EL9102, EL9620

Labels: Resins C-2120, BT-2110, DW10 SIS EL9126, EL9163, EL9470

BT-2104: It's mainly used in the field of Solvent-Based PSA, which has excellent compatibility with NR and good viscosity increasing effect.

BT-2110: It's mainly used in the field of Hot Melt PSA. The molecular weight distribution is narrow, and it has excellent compatibility with SIS group and good wetting ability.

C-2120: It has good compatibility with SIS/SBS, good wetting ability, suitable peel strength and cohesion.

DW10: It's a liquid at room temperature and has good compatibility with SIS/SBS, which can reduce the Tg of PSA and improve the low temperature resistance of PSA, and is often used in applications such as low temperature labels.

SIS EL9101, EL9102, EL9620: High cohesion strength, good pressure sensitive performance.

SIS EL9126, EL9163, EL9470: High diblock content, low modulus, good wettability, high die-cutting performance.

HB Group resin TR series and BT series can be widely used in Hot Melt Adhesives. It has the advantages of light color, good compatibility, suitable opening time and curing time, suitable melting viscosity, good temperature resistance and improved bond strength.They have excellent compatibility with a variety of polymers, including EVA, Metallocene, APAO, Polyolefin and others.

Corresponding grades and characteristics

Woodworking Adhesive mainly uses copolymer resins TR-100,TR-120 and C9 resins BP-120, BT-130, BT-140.

Book Binding Adhesive mainly uses BT-1200, TR-100. PM-100.

PM-100 monomer resin can improve the low temperature flexibility of Book Binding Adhesive, suitable for high-grade Book Binding Adhesive.

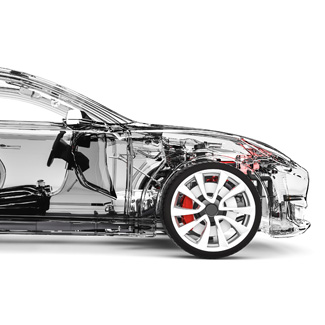

The BT series of HB Group resins can be widely used in Automotive Adhesives and Sealants,they have good compatibility with a variety of polymers and excellent water resistance.

Corresponding grades and characteristics

Mainly use C5 resin, such as BT-1200, BT-1200H, BT-2104.

Good compatibility with all kinds of polymers, water resistance, acid and alkali resistance.

Waterproof coil is mainly used for building walls, roofs, tunnels, highways, landfills and other places,It is a flexible building material product that can be curled into a roll shape to resist external rain and groundwater leakage.

Corresponding grades and characteristics

The waterproof roll is mainly recommend C5 products BT-2110, C-2120.

High requirements for roof waterproofing coils can use DW100.